Inline conductivity and online* Total Organic Carbon (TOC) monitoring in pharmaceutical water distribution systems has been used for final product quality verification for decades. One of the many benefits to this approach is real time measurement of these two critical quality attributes for both USP Purified Water and Water for Injection, allowing for immediate in-process improvements to be made. However, the economic savings from elimination of point-of-use (p.o.u.) sampling and offline laboratory analysis is also significant.

Chemical attributes of pharmaceutical waters, such as conductivity and TOC, are assumed to be homogenous throughout a given distribution network, and it is generally accepted that online data are substantially representative of the quality of water at use-points. This differs from regulated microbial quality attributes such as total viable bacteria and bacterial endotoxin which may have a certain degree of variability throughout the same network. Therefore, through a successful Process Performance Qualification, we are able to demonstrate a strong correlation among offline data (i.e. grab samples) and online data for chemical impurities. A risk assessment for this practice will typically result in parametric release based exclusively on online data as acceptable verification of the chemical integrity of the product water where it is used.

A Risk Assessment should also include a review of the use-point design and any downstream components in addition to an analysis of how the water is used. A contamination control strategy should be considered if there is a possibility of the water being compromised as it is dispensed. For the following examples, grab sampling may be considered appropriate based on the level of risk.

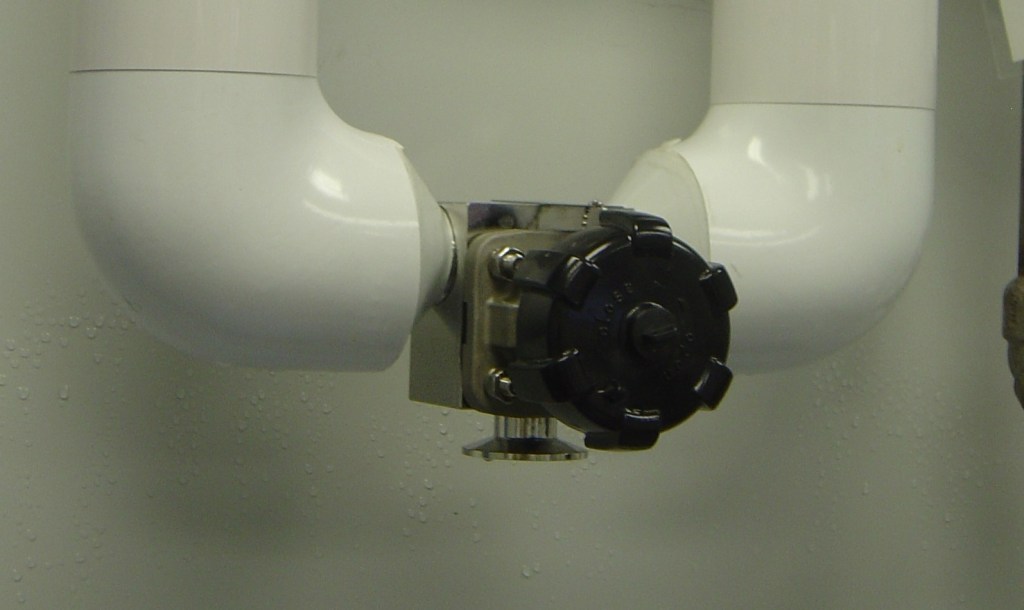

- Equipment Downstream of P.O.U. Valve

The addition of heating or cooling exchangers, or other process equipment, downstream of a p.o.u. valve invites the possibility of chemical contamination that would be undetected by inline sampling of the main process stream.

- Inline Sample Not Representative

USP guidance for pharmaceutical waters is clear in that the sampling of critical attributes should be as representative as possible. If an external device such as a hose, spray nozzle or wand, pipe extender, etc, is used to dispense water, samples should periodically be taken from the outlet of the additional component to ensure there is no added contamination. This sampling should be done in addition to a proper hose or device management program.

- Possibility of Back Contamination

If the p.o.u. feeds a pressurized tank or process equipment that could possibly back contaminate the distribution loop or drop, p.o.u. sampling may be required. This includes sub-surface tank fills.

- Inline Monitoring Location Not Representative

If inline monitoring locations for chemical attributes are located at the outlet of the generation system or in the distribution loop and not on the distribution loop return, they may not be most indicative of the quality of water at p.o.u. Any contamination of the distribution loop would be diluted as water is recirculated to the storage vessel. Optimal inline sampling locations should be established based on a risk assessment.

- Unmonitored Subloops

Subloops segregated from the main loop with no inline monitoring should be routinely sampled. Even those subloops which may return to the main distribution loop or a storage vessel where the contamination would be diluted should consider p.o.u sampling.

- Verification of Online Data Integrity

P.o.u. sampling and analysis can always be used to generate redundant data. This would reduce the risk if an inline instrument fails calibration or a TOC analyzer does not pass a system suitability test.

Additional examples may also exist beyond those listed above. The design, operation, and sampling program should all be validated. As all pharmaceutical water distribution systems are unique, different sampling protocols are established based on the risk and accuracy of the inline chemical sampling for each specific system.

*The terms inline and online are used interchangeably in the text. In-line data refer to parameters analyzed directly via an in-line process instrument such as conductivity, where online data refer to samples taken and analyzed from a sample loop or side stream such as TOC. Inline and online process analytics are generally continuous and do not involve transporting samples to a separate location for analysis.